Loading...

Model: YCCL

Cushion lock assembly with anti-cavitation checks

Capacity:

Loading...

Model

YCCLLHNAK

|  |  |  |

|

Control

Functional Setting Range

Seal Material

Pilot Ratio (4th Letter) of Primary Cartridge

Port and Material Designation

Function

Technical specifications

Modifiers

Ports

- B, B/SPorts V1 & V2: 3/8" NPTF; Ports T1 & T2: 1/2" NPTF;

- C, C/SPorts V1 & V2: 1/2" NPTF; Ports T1 & T2: 1/2" NPTF;

- J, J/SPorts V1 & V2: SAE 8; Ports T1 & T2: SAE 10;

- K, K/SPorts V1 & V2: SAE 10; Ports T1 & T2: SAE 10;

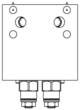

This valve assembly provides overrunning load-control, load-port relief protection, supplies make-up oil, and flushes hot dirty oil out of the actuator. All oil coming out of the actuator returns to tank through port T.

- The counterbalance valves should be set at 1.3 times the maximum load induced pressure.

- This assembly is ideal for applications with long lines to the actuators. Mounting the assembly close to an actuator ensures that cool, clean oil will be supplied to the actuator and that the hot, dirty oil will go out the T port to the tank

- Hydraulic motors leak. Therefore a mechanical brake is recommended to positively lock any stopped live load.

- Body TypeMotor mount

- InterfaceEaton/Char-Lynn H & S

- Capacity15 gpm

- Mounting Hole Diameter.34 in.

- Mounting Hole DepthThrough

- Mounting Hole Quantity4

Model CAD Files

Click the link of the file format you want to download.

Why doesn't Sun anodize their aluminum bodies?

How big is a drop of hydraulic oil?

Direct acting or pilot operated - what do I use?

- All SAE o-ring porting per ISO 11926. All NPTF porting per ANSI B1.20.1. All BSPP porting parallel thread.

- For detailed information regarding the cartridges contained in this assembly, click on the models codes shown in the Included Components tab.

- Important: Carefully consider the maximum system pressure. The pressure rating of the manifold is dependent on the manifold material, with the port type/size a secondary consideration. Manifolds constructed of aluminum are not rated for pressures higher than 3000 psi (210 bar), regardless of the port type/size specified.

Highlights

Technical Tips

Technical Information

- PartDescriptionQuantity

- 330-006-008*Plug2

- 500-002-908*O-Ring2